“RSC Box” or “Standard Box” is the most efficient type of box, created by simply folding and tucking its flaps, minimizing paper waste during production. It is crafted from high-grammage cardboard and is easily recyclable, making it environmentally friendly.

These cardboard boxes can accommodate various items and are versatile in their use. If the items require a flat surface or double-layer protection, the RSC box can be adapted by inserting a “fill-in pad” between its two flaps.

If you need a unique packaging, we can assist you in creating all kinds of curves, shapes, ventilation holes, or additional folds.

“Die-Cut” cardboard boxes are commonly crafted as self-locking units, eliminating the need for glue, tape, staples, or other closure methods. In other words, they are specially manufactured with exceptionally high quality materials.

The manufacturing process of Die-Cut boxes differs from standard boxes (RSC), allowing for greater variations in Corrugated Carton Box designs.

Produced in the form of rolls, Single Face Corrugated Cardboard is an ideal product for wrapping items that require protection and have irregular shapes.

This type is versatile as padding and shielding against damage, often combined with bubble wrap for heavy or large items. The material is 100% easily recyclable.

Our company is also a major supplier to various Converting and Minibox factories in Indonesia.

PT. Surindo Teguh Gemilang

PT. Sentralindo Teguh Gemilang

PT. Universal Jasa Kemas

PT. Sentral Kemasindo Teguh

PT. Karya Wangsa Investama

Teguh Group consistently maintains and enhances product quality, including staying updated with advancements in manufacturing machinery to elevate customer satisfaction on a larger scale.

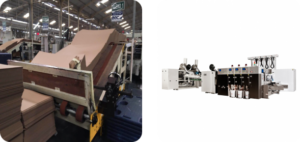

The central machinery in the corrugated carton box industry, this machine is capable of producing corrugated cardboard with varying thicknesses or grammages as per our clients’ requests, including B, C, E Flute, and Single Face E Flute.

Flexo-Folder-Gluer (FFG), a machine comprising several sections (feed section, printing section, creaser-slotter, in-line), transforms corrugated cardboard into corrugated carton boxes while enhancing productivity in the corrugated industry without compromising the quality of the resulting Corrugated Carton Boxes (CCBs).

Rotary Die Cutter (RDC), a die-cutter machine, replacing the traditional Auto Platten (a.k.a Flatbed), offers precision and accuracy in the die-cutting process (a.k.a corrugated carton shaping). With our array of die-cutter machines, we can effortlessly meet all carton box requirements, accommodating various shapes.

As an alternative technology to Flexo, we also possess gluers or stitchers, including the Wax Coater; Auto Folder, Semi-Auto, and Manual Stitcher, to ensure the strength and durability of the carton boxes produced by Teguh Group.

Adhering to international standards in our business operations, our work procedures comply with national regulations regarding environmentally friendly factory waste. Through the seamless combination of the Waste Shredder and Waste Baler, our factory can transform non-environmentally friendly residual materials into safe waste. With investments in modern waste processing machinery/technology like Auto Waste Water Treatment, we ensure that our wastewater is environmentally safe for the surrounding area.

Customer satisfaction is our top priority, which is why we conduct Quality Control on the raw corrugated cardboard materials as well as the final output of the corrugated carton boxes. In addition to common Corrugated tests, we also perform specialized tests. For instance, we use a Spectro-Densitometer to meet color printing standards and conduct Crush Testing to measure the strength of the corrugated medium.